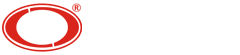

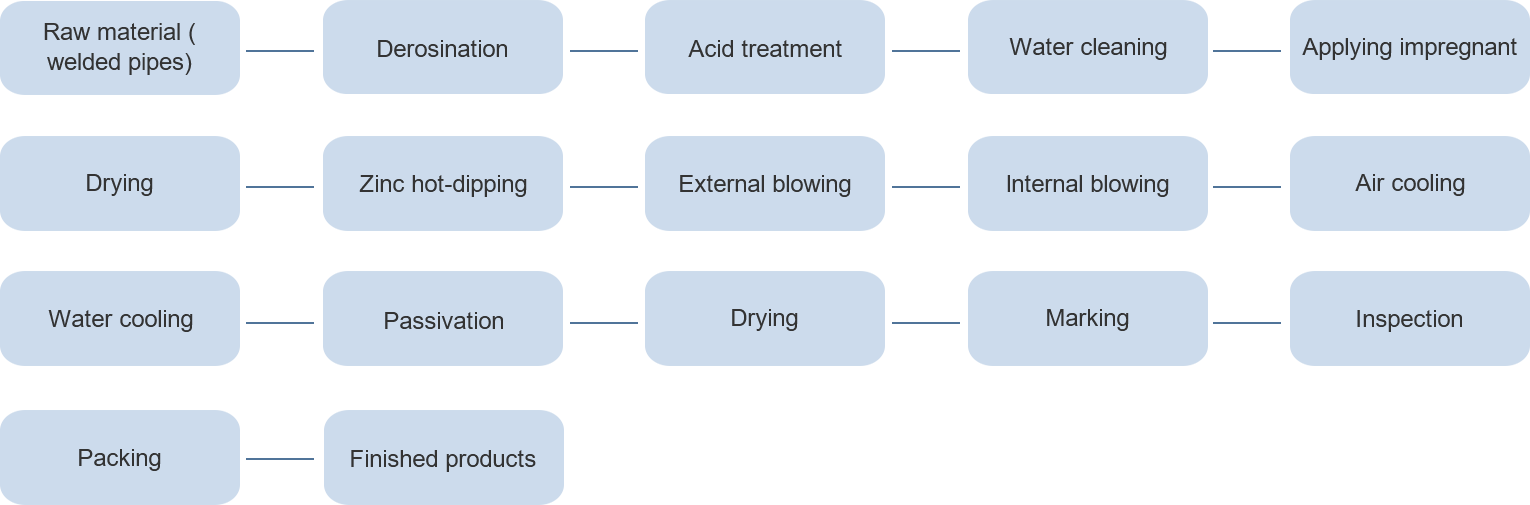

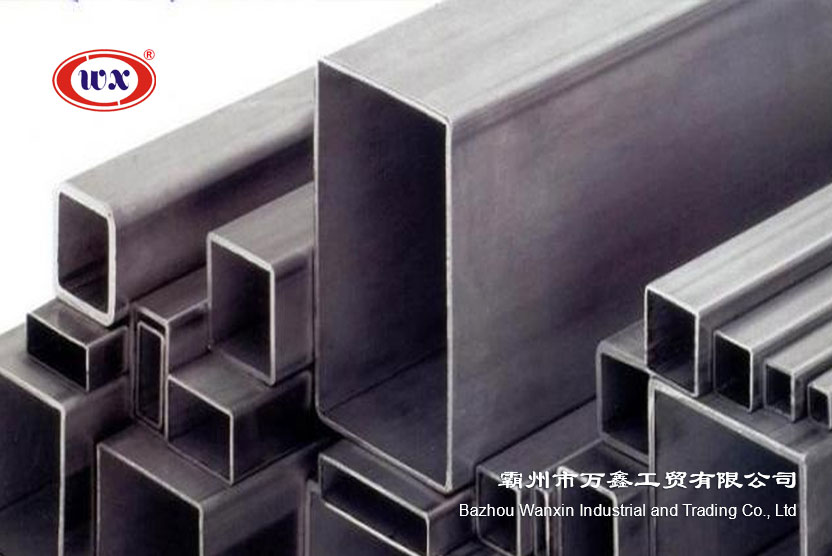

Steel pipe hot dip galvanizing production line is a production equipment that automatically dipped the finished black pipe after surface treatment and plated a layer of corrosion-resistant and smooth zinc layer on the inner and outer surface of the steel pipe. The main equipment of the production line includes drying furnace, heating furnace, galvanizing machine, steel pipe extraction machine, drawing mechanism, drawing roller, translation mechanism, steam and air combination blowing machine (or guide rod blowing machine), leveling mechanism, cooling water tank, spray roller, typing roller, blue belt machine, electrical parts, etc. Wanxin company production of hot-dip galvanized production line specifications between 0.5-10 inches.

Welding pipe galvanizing machine

Welding pipe galvanizing machine

Welding pipe galvanizing machine

Welding pipe galvanizing machine

Welding pipe galvanizing machine

Welding pipe galvanizing machine

4 minutes -2 inch welding pipe galvanized machine equipment

Number | Device name | Number | Device name |

1 | Drying oven heating body | 2 | Oven drive |

3 | Pan transfer mechanism | 4 | Galvanizing machine |

5 | Magnetic roll extraction | 6 | Bring up the roller table |

7 | Pull up, blow in, move the column horizontally | 8 | Traverse mechanism |

9 | Guide rod internal blowing mechanism | 10 | Electric levelling |

11 | Cooling tank | 12 | Roller loading chain mechanism |

13 | Discharge roller traversing | 14 | Discharge roller table |

15 | Roller table passivation device | 16 | Electric control section |

17 | Wrapping machine | | |

24-hour hotline

24-hour hotline

Home

Home Tel

Tel Product

Product